This website no longer supports the Internet Explorer web browser.

Microsoft is retiring and will no longer support Internet Explorer. Please use another web browser to access this website.

主菜单

Additive Manufacturing for Next-Generation Brake Systems

图像

Light and efficient: the added benefits of additive manufacturing

When it comes to the braking systems used on trains, 安全, 可靠性, and performance are always the number one priority. 在这些领域,威伯泰克凭借我们的Metroflexx和Regioflexx制动解决方案处于领先地位. Metroflexx sets the standard for the mass transit rail industry, while Regioflexx is our latest-generation solution for suburban, 城际, 区域, and high-speed trains.

As well as being as safe as it gets, both systems are also among the lightest and most efficient on the market, which brings significant benefits for train operators. 我们的工程师通过两个主要的设计和制造特点实现了这一点:使用软件而不是气动组件, and additive manufacturing. By leveraging these innovative modern solutions, we boost the 可靠性 and performance of both brake products, while lowering maintenance and installation time and costs, and creating multiple efficiencies.

An innovative approach to brake design and manufacturing

When developing Metroflexx and Regioflexx, 全球最大网赌正规平台通过在相同安全级别的软件仿真中替换制动系统中执行安全关键功能的一些气动元件,实现了重大飞跃. 这样做的好处是显而易见的:实际上不是物理产品的组件除了开发和验证之外不会产生任何成本, 没有重量, creates no installation constraints, and requires no maintenance. While pneumatic components require project-specific settings, once replaced by emulation software, 设置被只需要为项目固定一次的软件参数所取代.

这种变化是创新的,全球最大网赌正规平台本可以止步于此,但我们决定走得更远. 为了减轻重量,使我们的产品对客户更有利,我们选择探索在其余气动部件上使用增材制造.

When additive manufacturing is added to the mix

Pneumatic components are traditionally made of aluminum, either machined in aluminum billet or, when manufacturing volumes permit, 在同一. 每个部件都是在一个钻孔或粘合面板或管道安装法兰, 气动元件与其支架之间的每个接口都需要紧固件和密封件以保证密封性. 同时,该系统确保组件可以轻松拆卸以进行维护, 使用额外的部件是有代价的:在刹车系统大修期间,每个接口的密封都需要更换,并且容易泄漏. 这意味着维护成本的增加和可靠性的降低,以及额外的重量.

When 全球最大网赌正规平台 was developing Metroflexx and Regioflexx, 增材制造技术已经给许多行业带来了革命性的变化, 包括铁路. 虽然我们的工程师已经最小化了Metroflexx和Regioflexx中使用的气动元件的数量, 我们还希望充分利用这项新技术,进一步推动物理集成,并最大限度地减少所需的气动接口数量.

Improvement in all areas

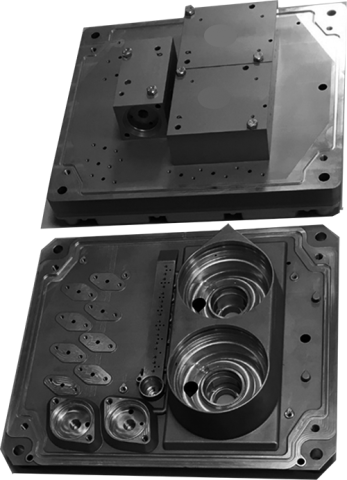

The top image in figure 1, 下面, 展示了Metroflexx主板的初步设计,铸铝和关键气动元件在板上法兰连接, with seals at every pneumatic interface, 加上螺丝. 下图为采用增材制造设计的同一metroflexxx板材的设计.

图像

图1:带有浇铸板的Metroflexx初始版本,以及3D打印版本

Additive technology brings multiple benefits: to the product itself, to how it is produced, and across its full life cycle.

物理集成

- 关键气动元件的阀体完全集成在板体内, limiting the number of pneumatic and mechanical interfaces. 除了, the number of seals is greatly reduced, thus improving 可靠性 and reducing maintenance costs.

- Internal piping is greatly optimized, improving pneumatic performance. Component placement on the plate can also be optimized, without machining constraints, making maintenance easier.

- 3D打印版本的Metroflexx将不少于32个独立的部件合并为一个组件.

重量改善

In traditional brake control equipment with an electronic rack, a pneumatic brake panel and wheel slide protection valves, the brake control weighs around 70kg.

Metroflexx, which replaces traditional brake control equipment, weighs 15kg in the initial design with a 在同一 aluminum plate. When produced with an additive manufacturing plate, Metroflexx’s weight drops to 10kg, representing a 33% weight improvement. The 5kg difference does not have a major impact on train payload, but makes a huge difference in terms of maintenance. As a line replaceable unit (LRU), 在10公斤, Metroflexx(或Regioflexx)可以由一个操作员在不到20分钟的时间内在火车上更换,而不需要任何特殊工具, 这意味着维修或大修可以在一个专门的车间进行,而不会影响火车的可用性. 在10公斤, Metroflexx和Regioflexx是目前市场上最轻的集成制动控制系统.

处理

加工时间减少80%,生产零件所需能量减半. 我们的供应链变得更加灵活,因为我们不再依赖铸造供应商. 这就减少了对运输的需求,并能够根据需要订购数量, with no minimum requirement.

设计进化

The design is fully flexible, 因此,只要改变相关的数字模型,就可以根据需要进行修改, thereby eliminating costs related to tooling modifications.

图像

图2:带有浇铸板的Metroflexx初始版本,以及3D打印版本

Exhaustive testing to guarantee 安全

When it comes to 安全-critical equipment like braking systems, 全球最大网赌正规平台 takes testing and validation of our innovations very seriously. Additive manufacturing is no exception. 我们的产品经过了最严格的测试,以验证其主要安全特性.

- 我们研究了如何确保气动通道保持清洁和无污染, specifically in piping and components.

- 我们的实验室进行高压液压和疲劳测试,以确保产品在压力下的坚固性.

- 产品经受了冲击和振动,以确保它们能够承受真实的火车环境.

- We conducted environment tests, 其中包括将产品暴露在极端温度和盐雾中.

这项广泛的验证计划使我们完全相信,这项技术可以保证与传统制造的气动系统和组件相同的安全性和耐用性.

Additive manufacturing: layer upon layer of benefits

使用增材制造提供的优势是无数的,不能夸大. This technology not only reduces the weight of parts produced, 它还可以实现产品功能集成,从而限制对设备维护的需求. It shortens manufacturing times and lead times for spare parts, while also lightening up the supply chain. 这些好处, which are advantageous for train operators, 对环境也有好处,因为它们通过显著降低能耗使制造过程更加环保.

前进, 全球最大网赌正规平台最近决定在图尔建立一个欧洲增材制造中心, 法国. The site has capabilities to manufacture polymer and metal parts, and offers services for the entire value chain, from design consultancy, proof of concept execution, and support for validation and certification, to 3D printing and post process (machining, 绘画, 表面处理……).

我们致力于释放这项颠覆性技术的潜力,创造更可靠、更高效的制动系统,帮助铁路运输业加速迈向更安全、更环保的未来.